For lots of fountain sparkle in the sunlight plus additional fountain sound – a spray ring will fit your needs nicely! And adding a copper spray ring to your fountain is a relatively easy thing to accomplish, even if it’s years after your fountain was originally installed.

- Sometimes the decision to add a spray ring later is made for the following reasons:

- There wasn’t enough initial budget for the project to supply it when the main fountain was being installed.

- If there has been a change at your estate – for example maybe there are a lot more annoying traffic noises in the area which you would like to muffle with the sound of your fountain.

- Or, maybe you just want to add a bit of PIZZAZ to the fountain you have now, as fountain spray rings tend to cause a lot of sparkle on sunny days?

- Normally the spray ring can be made to fit right over the top of the centerpiece in your fountain.

- And then all you have to do is connect it to a pump (large enough to pump the arcs of water to the height you would like).Then, connect the pump to the power source (temporarily) and turn on the pump.

- Once it’s running for that initial time, you’ll likely have to wade into the pool to adjust each of the nozzle directions by hand (and then tighten down the nut to finger tight).

- This is to make sure the arcs of water are all shooting the correct direction, and all arcs are equidistant apart where they are landing in the central bowl.

- Maybe you installed a relatively quiet fountain, with just a few rivulets of water coming off the central bowls and then hitting the pool below, and you would now like to make the fountain more of a welcoming statement piece at the front of your residence.

In terms of the pump needed to run your fountain:

- You can either leave it as a 2-pump system – with one pump to run the centerpiece and then a separate pump for the spray ring.

- And that way, if it’s really windy, or if you temporarily want a much quieter fountain for some reason (maybe during a wedding ceremony) – you can turn off the spray ring and just run the centerpiece alone for now.

- Or, you can get a large enough pump to run the spray ring AND the centerpiece at the same time, and connect the water hoses from the centerpiece and the spray ring to the pump with a manifold that has valve handles on it.

- Then, with those 2 valves, you can control the height of the spray ring water vs how fast the centerpiece water is going.

Of course, the size of the pump (or number of pumps) needed to run your fountain spray ring is affected by the following things:

- Number and size of nozzles in the ring.

- The size of tube the nozzles are inserted into.

- Number of places the pump is feeding the ring

- How high you want the arcs of water to go.

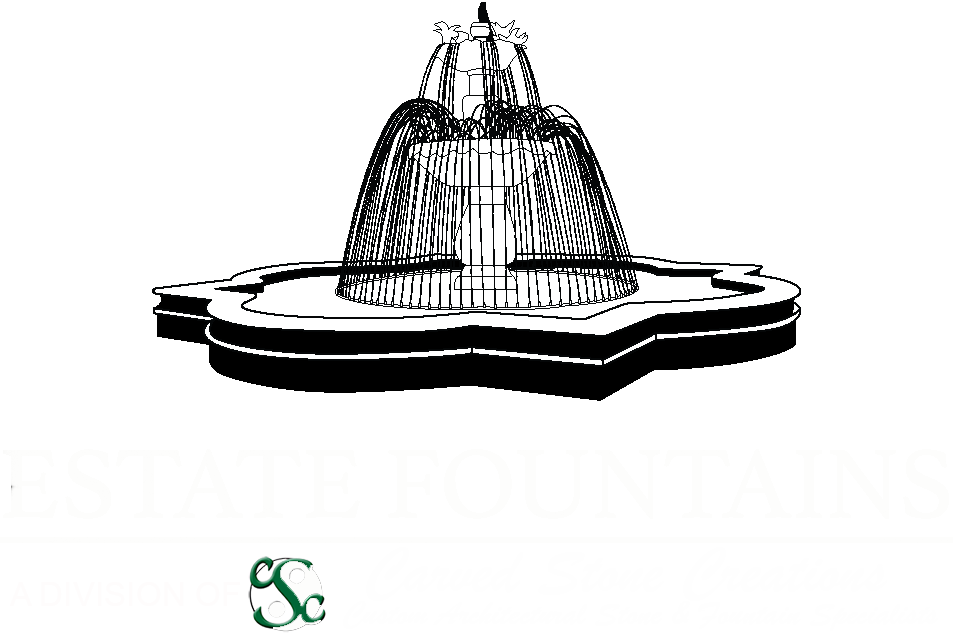

- For Example, check out the following videos that show a 12’ Copper Spray ring with (100) 3/8” nozzles in as 16’ Pool surround.