Before you purchase and install a fountain spray ring, there are a few things you should know first (when designing it) – as we have learned the following things over our years of making them for customers:

- First you should think about how TALL you want the arcs of water going in your fountain.

- Many times, people will have the arcs of water land in the bottom bowl of a tiered centerpiece, and in that way – it causes a huge influx of water to pour off that bottom bowl – which contributes to the much louder fountain noise.

- Or, some customers want the arcs of water to shoot up WAY taller than that…

- It’s all a matter of preference.

- Or, maybe there isn’t a centerpiece planned to be in your fountain at all?

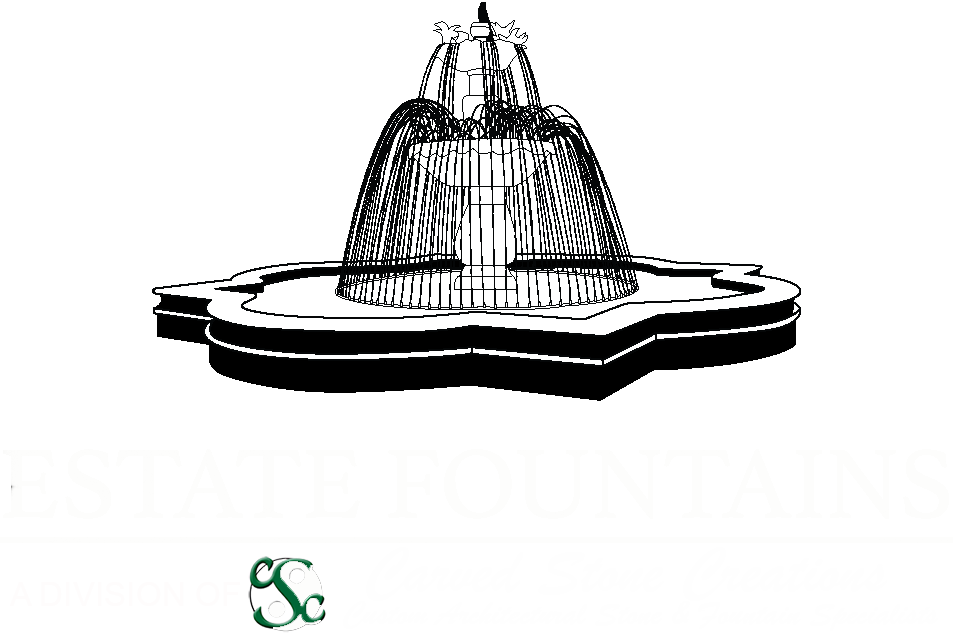

- Here is a pretty spectacular fountain in a granite pool surround, with (40) 3/8” adjustable fountain nozzles and a central 1.5” NPT Frothy Serac Nozzle. (It loses a lot of water with how tall that central column shoots, but it looking amazing anyway!)

- Vs. a more sedate spray ring option in a much smaller fountain.

- Or, if you have a fairly large pool area, you could install an OUTWARDS facing copper spray ring, and in that way – you can save some money on the cost of the copper spray ring itself, and get a similar look.

- But, that will only work if the arcs of water will come down in a location far enough away from the exterior wall of your pool area, that it won’t cause constant water loss from water splashing right outside of your pool.

- Since as far as water is falling VERTICALLY is how far its going to splash HORIZONTALLY, so you’ll need to know that information to measure your pool surround – to make sure it’s large enough, vs how tall you intend to shoot the arcs of water.

- Of course, there ARE pros/cons to how far up in the air you shoot those arcs of

water though.- We have learned that for example – in an 8’ diameter spray ring, if you shoot the water up higher than 4’ tall, it creates a higher angle to the water that makes it easier for the Wind to push the arcs out of alignment – which would possibly cause some water loss or slip/fall hazards, with water landing outside of the pool area.

- Also, if you are losing chlorinated water outside of your pool, it tends to kill nearby foliage/flowers / bushes that may be sensitive to the chemicals in the water.

- Or, if it’s unavoidable (that sometimes you are losing water because of strong wind pushing on the fountain), then plant hard leaved foliage around the fountain (IE Irises are a good option) – as they won’t be nearly as affected by chlorine issues.

- Vs. if you had something like roses planted around the fountain – they will start to look very bad very quickly with all the brown spots on the leaves from chlorine damage.

- So, normally we recommend shooting the water no higher than the radius of the spray ring.

- And if you are in a very windy location, having the arcs of water at an even lower angle than that would make them even more resistant to wind misdirection.

- We have learned that for example – in an 8’ diameter spray ring, if you shoot the water up higher than 4’ tall, it creates a higher angle to the water that makes it easier for the Wind to push the arcs out of alignment – which would possibly cause some water loss or slip/fall hazards, with water landing outside of the pool area.

- Many times, people will have the arcs of water land in the bottom bowl of a tiered centerpiece, and in that way – it causes a huge influx of water to pour off that bottom bowl – which contributes to the much louder fountain noise.

- Next, you should consider the actual nozzles that will be installed / soldered into the

spray ring:- We have noticed that 3/8” NPT and larger fountain nozzles seem make your fountain pool fairly resistant to water loss caused by gusts of wind (misdirection.)

- Vs. using smaller nozzles (like 1⁄4” or 1/8” NPT nozzles) make it VERY easy for gusts of wind to throw the arcs of water around, which could cause your fountain to run dry very quickly – if it’s a windy day.

- And typically the bad thing about that would be….

- Normally fountain pumps are water-cooled, so if you have the pump running with hardly any water in the pool, sooner or later it’ll seize up the pump, and you’ll have to buy a new one to get your fountain running again.

- Of course, the size of the nozzles also has a large impact on the cost of the spray ring as well, if you are installing 60 – 100 nozzles in the ring.

- Thus, why sometimes you could accidentally be comparing apples to oranges when doing price checks between manufacturers.

- Because not only does it matter how many nozzles are shown (IE how many times someone had to drill / solder a nozzle into the ring…)

- But, even if you are looking at a similar diameter spray ring, with a similar number of nozzles – sometime they aren’t a similar size nozzle at all….

- Also, using “adjustable” fountain nozzles is a very good idea…

- And that way, if for example something is a little bit out of level (legs on the ring, floor of fountain, exact location the nozzles was soldered into the ring)

- If you have adjustable nozzles – it won’t matter at all – because you’d be able to adjust the location of where the arcs of water are landing.

- Vs. if you have nozzles that are NOT adjustable, it’ll be much harder to get the arcs of water looking all symmetrical.

- FYI, an adjustable nozzle comes in 3 pieces, the actual “nozzle”, the nut that it moves around in and then the seat that actually screws into the spray ring.

- You cannot just use only 1 or 2 of the pieces, they are a SET needed to make the nozzle work correctly, and the thread pattern of the bottom part ONLY goes with that specific nut.