We had a customer contact us about an antique concrete fountain they had at their home, which had slowly been falling apart, cracking, and leaking over the years, and they finally decided they needed to do something to resurrect it.

- The dismaying thing was this damage had been occurring even though they had been consistently covering the quite large fountain with a tarp before the freeze/thaw seasons of Southern Wisconsin, and living with a bit of an eyesore in front of their home for the 5 – 6 months of Fall /Winter / early Spring for years upon years.

- This typically happens if there are small pinholes in your tarp or if there is any condensation on the underside of the tarp PLUS the fact that you can’t stop water from coming up UNDERNEATH the fountain from the ground.

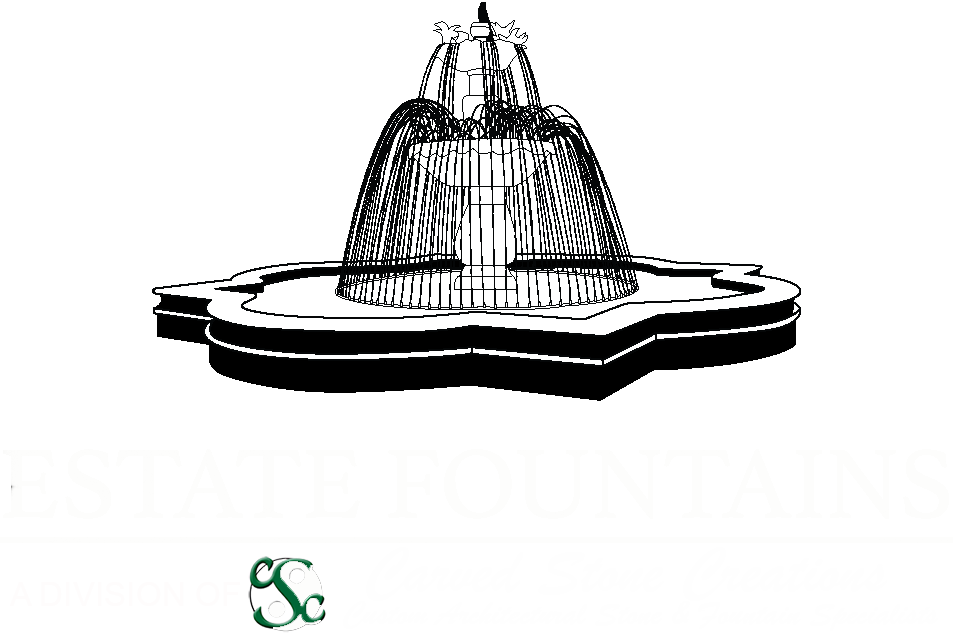

- The following are photos of what their fountain looked like originally, and the photos we sent to the carvers to get an initial quote for the project. (In this instance, the customers decided they want a bit larger of a fountain than the original concrete one, as well as matching granite pool coping and nearby benches)

Thus, began the process of re-creating their fountain in Golden Cypress Granite, so they’d never again have to cover their fountain, but could enjoy its pleasing shape all year round, even while the fountain is covered with icicles or snow.

- This is possible because Granite is a non-porous stone, which not only LAUGHS at snow and ice, but is amazingly easy to clean / maintain if the water in your fountain has calcium or iron in it, which causes a milky white film or orangey / red iron stains on the stone surfaces.

- Check out this blog post to learn more about which commonly available cleaning products can make your GRANITE fountain cleaning a breeze!

- Vs. if you have a more porous stone fountains (like Marble, Limestone, Travertine, Cantera or concrete) – you’ll need to use much gentler cleaning products, be consistent with your fountain cleaning chores, and use a lot of elbow grease instead.

- Here is a blog post that explain more about WHY granite is the best option for fountains in a freeze/thaw climate, and why granite fountains will last GENERATIONS in those regions of the country.

- Vs. more porous stones will only last a fraction of that time in those same areas. (And in the instance of Cantera or concrete, that “fraction” of time can be as short as only 2 – 3 years, particularly if you don’t cover the fountain before freezing weather arrives!)

Honestly, we would NEVER recommend the very porous Mexican Stone called Cantera ever be used for a fountain, as even the chemicals typically used in fountains to keep algae out will eat that stone like alka seltzer in a glass!!

So, our first step in the Special Order Fountain (or statue) process (after the 50% down payment is complete) is to get a shop drawing set started, and approved by the client before they are sent to the carvers to start their part:

- Shop drawings essentially show “big picture” type details, sizes of stones needed for each part, general shape/size of each piece of the fountain, hole sizes needed for drainage or plumbing, etc.

- Plus if there are any specific carving details the customer wants, those are sent as supplemental photos in the shop drawing set.

- Normally we just direct customers to find those carving details on google images, and find exactly what they want (from any photos around the world) even if they are a detail not actually carved in stone, but rather wood / resin / ceramic / etc.

- And those photos are what we’ll send along with our shop drawings, to explain to the carvers how the fountain should look.

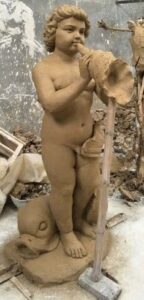

Then, the next step is to get a clay model done, so that the details of the most important pieces of the design are definitely as the customer wants them before the carvers start actually carving the huge granite boulder pieces.

- This tends to really only happen on statuary designs, as other designs like egg dart, acanthus leaf details, etc are very easy to explain with photos of those details.

The following are the clay models we did for this particular fountain, to ensure the customers liked the look before the artists went further

Then, once those details were approved, we went onto the granite carving portion of the project, then sent photos to the customer once all of those parts were carved to get their approval before the items were all crated and sent on their way to our shop here in Wisconsin.

- Honestly, when a 40,000 lb shipping container arrives at our location, it feels a little like Christmas Day, to be able to take the tops off the crates and see all the amazing carving details on the special order items!

- So, we just absolutely adore it when we get photos from the customers after the items are installed in their final locations, as by then (with the length of those projects), it almost feels like getting a hug from an old friend after they’ve been away for a long time!

And these are photos of the fountain once it arrived to our Wisconsin shop:

- Since in this instance, the customer wanted our guys to install the fountain for them, we unpacked the parts which needed to have plumbing installed in them before the install day came.

- Or, if you are intending to have a local landscaper install the fountain for you (including the plumbing), when the crates arrive we complete a visual inspection to make sure the crate is not damaged in any way, and peek at the carving details through the crate, then schedule the shipment to your location as soon as the project is paid off in full.

- Notice how we sprayed some of the parts with water, so you could see the color the Golden Cypress Granite turns when it’s wet.

- And if you like the dry color better, you’d seal it with Miracle 511 Impregnator sealer, and even when the fountain is running, it’d stay that dry color.

- Or, if you like the darker color better, and you want the fountain to stay that color even in Winter when the fountain is NOT running, then you’d seal it with something called Miracle 511 Seal / Enhance sealer.

- Or, if you don’t care that the stone is a bit of a chameleon in terms of color, there’s no need to seal the granite at all. (Though just so you know, sealed stone IS a bit easier to keep clean than unsealed stone…)

Plus this is what that fountain sounds like when it’s running.