The village of Kenilworth IL has long been the proud owner of a community fountain at a central roundabout near their city hall location. The original idea was that they “wanted a hospitable entrance” to greet new visitors arriving from the train station. Thus a fountain of running water was constructed in the center of the open square.

According to the Encyclopedia of Chicago History: “The fountain was originally designed by George W. Maher, a contemporary of Frank Lloyd Wright. Maher lived in Kenilworth and saw nearly 40 of his designs constructed between 1893 and 1926. His designs plus Kenilworth’s distinctive stone commuter train station built in 1890, its numerous Tudor revival residences, and the Old English–style street lamps continue to evoke the pastoral image of an earlier time and vision of community.”

Per the Kenilworth Historical Society, the fountain was originally constructed in 1910. As you can see from this photo, it was an idyllic time of top hats, tails and ornately bustled dresses as passersby admired the sparkling grandeur of the new limestone fountain.

Since Limestone is a porous stone though, it’s not really known to last all that long in the freeze / thaw climate of really any location north of Dallas TX.

Our general “rule of thumb” is if you live in growing zone 1 – 8, you really should have a fountain made of granite, in order to have a very long-lasting fountain and carefree maintenance for generations.

- As other more porous fountains (like marble, limestone, travertine, cantera and concrete) tend to start to crack when they are rained on (or get wet) in Fall and then the moisture sinks inside the stone, and then freezes that night.

- So over time – those micro cracks deep within the porous stone get larger and larger before portions of the stone just start to cleave off the main structure, kind of like large swaths of ice off an ice burg.

Therefore, the City of Kenilworth’s Public Works Department had a difficult task, trying to keep that fountain looking like the jewel it had always been intended to be.

- According to our discussions with the City Manager, for about 30-40 years they had been covering the fountain surfaces with concrete periodically, trying to disguise the cracks / chips on the surface of the limestone.

- And as you can see, the porous concrete didn’t fare much better, in terms of its ability to stand up to the seasons, as well as dirt / algae.

Thus, with such a visible location in the middle of a roundabout, and probably several 1000 cars passing it every day, there were lots of passersby (and possible donors) concerned with the dilapidated condition of the fountain and its spray ring / bronze fish finial centerpiece….

- Especially when the local Garden Club would plant their gorgeous flowers around the fountain each Spring and would get a very close look at the damage.

- So, in 2020 Carved Stone Creations was commissioned to re-create the fountain out of a stone that will last a LOT longer than the original fountain, but in a similar light beige color to the original limestone.

- Thus, the city selected our Golden Cypress Granite, for a fountain option that’ll last generations!

You can see in this following demolition photo the layers of concrete cracking away to reveal the original stone underneath, which was a little darker than the concrete that covered it.

Then, our crew brought the fish finial back to our shop in WI, to give it a much-needed cleaning and rebuild of the spray nozzle in its mouth.

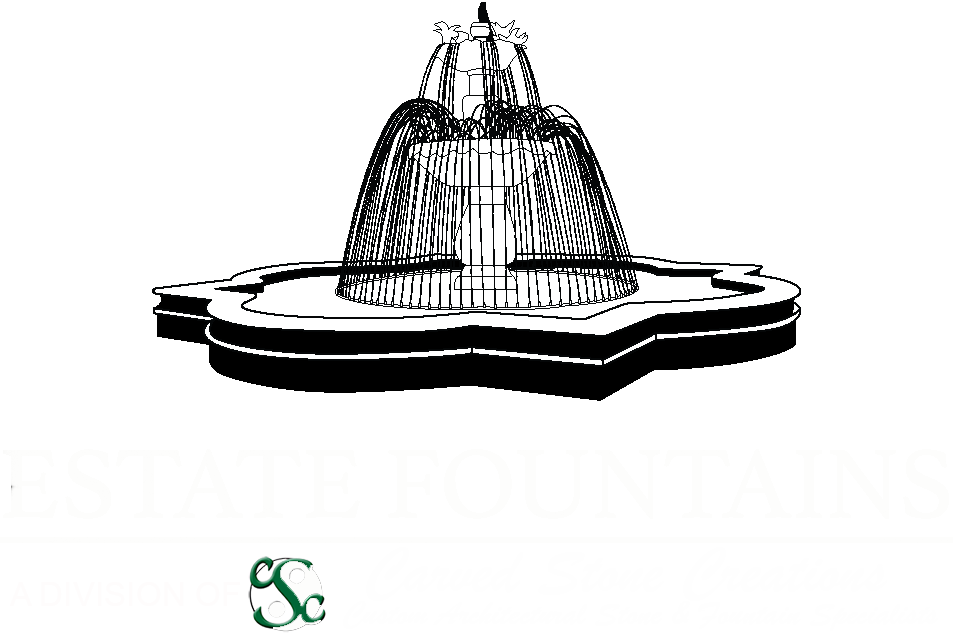

After the new granite parts were hand carved into the same shape/design as the original fountain (from the original 1910 design – not what it looked like with all the concrete added onto the centerpiece foot to keep it from toppling over with its cracked structure).

- It was then time to install those granite parts in the center of that very busy roundabout.

- The good news is only ¼ of that roundabout had to be blocked off for about 4 hours, and then the large telehandler could be moved away to let the traffic pass normally and glance in wonder at the workers laboring in the middle, working on the spray ring, lights, caulk, etc.

- The above is how the granite pool surround curb pieces are installed, with a ¼” seam between each piece (temporarily held apart with cardboard while each curb is set.) And then those seams are filled with a vertical grade/non-slump pool caulk, to make a waterpoof pool.

- The above is what the pool surround looked like right after sealing it with Miracle 511 Impregnator sealer, to keep the stone the lightest color possible – even when it’s raining or the fountain is running.

Lastly, here is what the fountain looked like and sounded like for their annual 4th of July Parade.

- We are very proud of how this fountain turned out!

- And so happy for the Village of Kenilworth – that they no longer need to spend so much money / time each year on their fountain maintenance!